Extractables and Leachables Sample Preparation: Too Complex to Automate?

One of the many complaints about manual sample preparation procedures is that they are often complex and as a result, take a long time to carry out. This is a reason that analysts and laboratories turn to automation, to reduce this burden.

However, those not familiar with lab automation may think, can automation really perform these lengthy, complex procedures?

The answer, thankfully, is yes. Here is an example from a recent piece of work we carried out for an extractables and leachables (E+L) workflow for analysis of a liquid drug product containing many excipients, most notably polysorbate which can be tricky to deal with.

The extraction involved liquid-liquid extraction (LLE) carried out twice:

- 1 mL of sample

- Aliquot of acetone

- Aliquot of ethyl acetate

- Shake for 1 minute

- Centrifuge for 6 minutes

- Transfer extract

- Repeat process with further aliquot of ethyl acetate

- Store sample/inject.

Whilst performing this method manually could be a lengthy undertaking, for an automated platform, it is relatively simple. LLEs are now commonplace for automated methods which makes development of this type of extraction relatively quick and easy. Moreover, automation enables us to reduce extraction times down to just a few minutes. Here mixing time is just 1 minute.

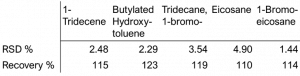

The results gained from this type of method also attest to the high reproducibility and performance of the automated method. Figure 1 showing the results obtained from a sample spiked to a level of 6 ppm.

Figure 1. Precision and recovery reuslts from extraction of a sample spiked at 6 ppm

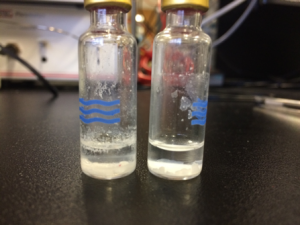

You may be thinking but what about the sample matrix, does this cause you problems? The answer can sometimes be yes, but with development these problems can be reduced or entirely removed. Figure 2 shows an extracted sample post-centrifugation. Here we can see a layer of precipitated matrix, which is presumably the polysorbate contained within the sample and other salts/excipients which has formed at the phase boundary between sample and extraction solvent. Automated centrifugation helps with removal and coagulation of emulsions and solids from extract layers, therefore problems caused by precipitates are much reduced. Any remaining dissolved matrix in your extract would need to be dealt with further clean-up steps if necessary.

Figure 2. Sample post-centrifugation

For this method, further sample preparation steps were carried out with automated solvent exchange. Solvent exchange is most often employed to transfer analytes into a solvent more amenable to the instrument chosen for analysis, in this case GC. Evaporation steps sometimes also have an advantage of removing excess matrix from a sample, especially if the matrix is poorly soluble in the solvent of choice. Figure 3 shows the result of an automated solvent exchange process going from an acetone/ethyl acetate extract to isooctane with further precipitation of matrix during the process leading an extract with matrix levels reduced even further. As the analytes are soluble in the end solvent these are dissolved with gentle shaking.

Figure 3. Sample extract after solvent exchange. Further matrix precipitation visible leaving a cleaned extract ready for injection

Here we have demonstrated a few key things about automated workflows in an Extractables and Leachables (E+L) setting:

- Complex and/or lengthy sample preparations can be carried out

- High degree of precision can be obtained

- Complex matrices can be handled.

All these positives enable us, the analyst, to focus on the more important aspects of sample analysis such as data interpretation and interrogation.

DOWNLOAD our new E+L Application Note HERE

If you have a complex sample preparation method and would like Anatune to assess the feasibility of Extractables and Leachables automation, please CONTACT US.

Previous post

6 Weeks to go until Future Focus