Geosmin – An Earthy Problem

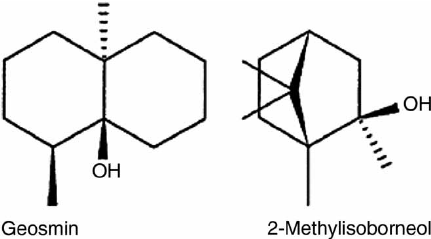

The water industry seems to be in a constant battle with taste and odour issues – the biggest culprits being geosmin and 2-methylisoborneol, or MIB as it is more commonly known.

Geosmin analysis has routinely been performed with liquid-liquid extraction using huge amounts of expensive and large amounts of in-environmentally friendly dichloromethane. Whilst this analysis has been the go-to for some time, is just doesn’t have its place in a modern automated world. Being very time consuming and often subject to contamination.

The question on everyone’s mind is: Is it possible to analyse for these compounds without spending copious amounts of time, money and effort? Yes is the answer!

We at Anatune have taken this old school method and given it the automated treatment. Whilst still being a liquid-liquid extraction using DCM as a solvent, everything about it is vastly smaller. Instead of a sample size upward of 500ml, it is now using 6ml, and instead of 50-100ml DCM, the process now uses 200µl: a big decrease of 250 times less solvent. The environment and the company wallet can relax.

Achieving low limits of detection is always an importance when dealing with taste and odour causing compounds, as most can be detected by the human nose in the parts per trillion range. Using this new automated solution, LODs of 1-2ng/l can be easily achieved; a great achievement considering that the solution uses 99% less sample compared to that of a method using 500ml. This could only be possible with improvements to instrumentation.

Advances in mass spectrometric detection has made concentration steps redundant. On a typical method, a concentration factor of about 500 can be achieved. The automated method has a concentration factor of 30, but coupling this with large volume injection and an Agilent 5977B high efficiency source MSD gives you the ability to reach those low LODs without needing vast amounts of sample and solvent. Achieving these low LODs is also helped along by using glassware that is not reused – eliminating the need to clean glassware can eliminate the potential for contamination introduced in sample preparation.

Time is also very important for labs processing a high number of samples – dictating reporting times and sample capacity. These parameters also take precedence, especially when it relates to taste and odour complaints and water companies needing to take actions. With the automated solution that Anatune has developed, one sample can be extracted and analysed within 30 minutes.

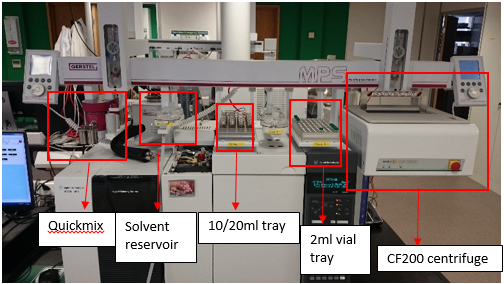

It is worth mentioning the GERSTEL QuickMix. Manual shaking of samples can be quite hard to match. Whilst bench shakers and other equipment do exist to shake samples, this is hard to replicate and attach to a GERSTEL rail. The Agitator is good at gentle mixing, however the QuickMix enables you to mix samples up to 3000rpm for a 10ml vial. This enables food solvent/sample mixing giving a good surface area at the phase boundaries and maximising extraction.

The setup for this solution is also very simple and very flexible. Being liquid-liquid extraction solution, this very same arrangement can also be used for all those other methods such as PAHs and pesticides that utilise solvent extraction; effectively turning a one method solution into a three in one purchase.

So if you find that geosmin is starting to become more than a malodour, keep in mind that there is a solution that can help you on your way. Analysis doesn’t need to be stressful or costly. An application note will be released shortly that provides more detail on the analysis and robustness of this method.

Call us now on +44 (0)1223 279210, or email: enquiries@anatune.co.uk if you would like to know more.

Previous post

Efficient Doping ControlNext post

Why We Won